PEKOS METAL SEATED

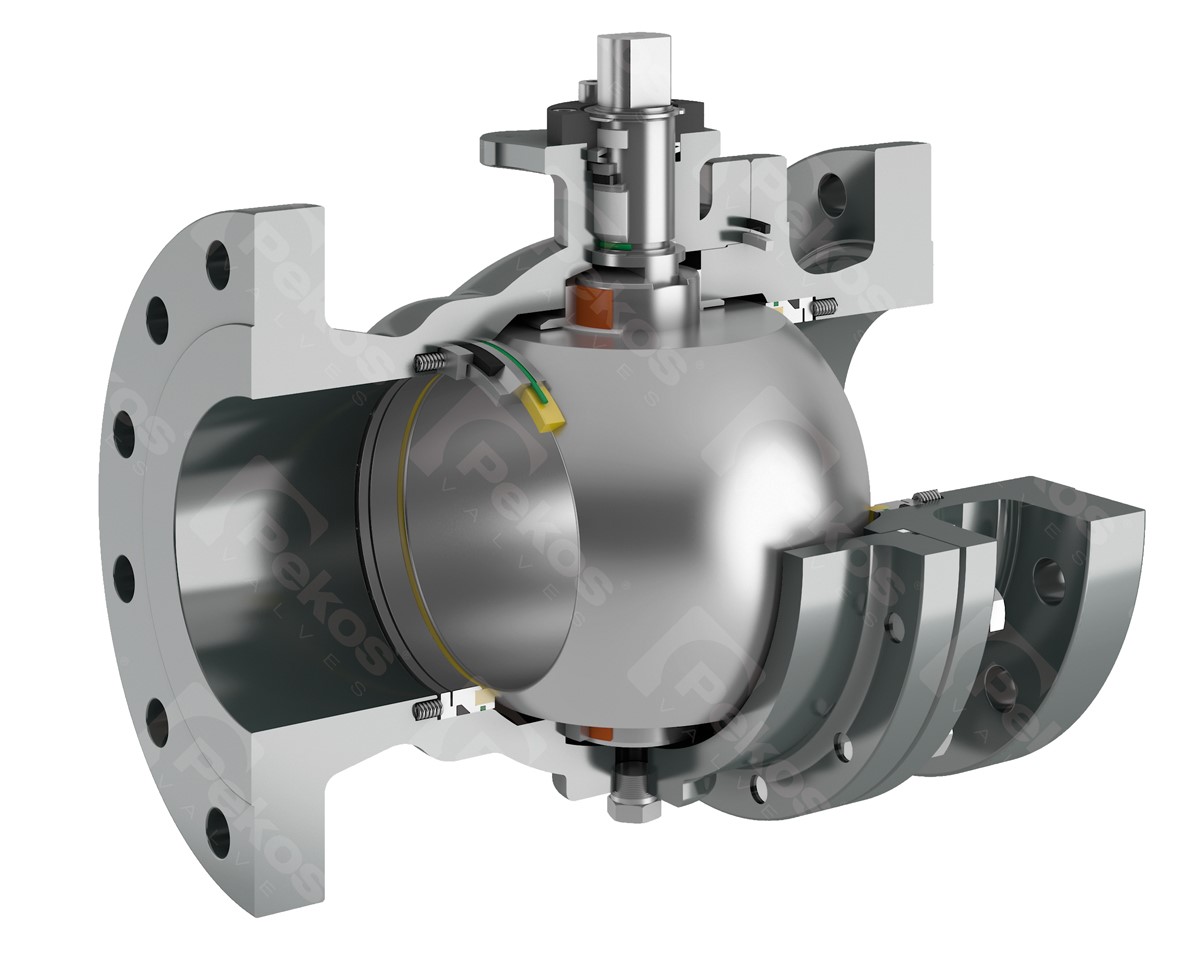

PEKOS metal seated ball valves are available with flanges, threaded and welded ends. Metal seated ball valves are mainly used at high temperatures or in applications where there is erosion and other influences that destroy soft sealing valves such as PTFE.

Delivered in accrdance with EN 558 DIN from DN15 to DN300 with pressure class PN320 up to DN400, DN15 to DN500 with pressure class PN160 up to PN250 and DN15 to DN1050 with pressure class from PN10 up to PN100.

Delivered in accordance with ANSI B16 from 1/2 ”to 12” with print class 2500, from 1/2 ”to 20” with print class 900 up to 1500 and 1/2 ”to 42” print class 150 up to 600.

PEKOS metal seated ball valves are delivered in several designs, such as 2-piece ball valve ZMS 04/06 with floating ball, full bore and short construction length. Top entry ball valve with floating ball or Trunnion top entry ball valve with guided ball, full bore or reduced bore and with cryogenic design. Trunnion 2-piece ball valve ZGMS 04/06 and Trunnion 3-piece ball valve ZGKMS 24/26 with guided ball, full bore or reduced bore design.

PEKOS 'product range consists of ball valves that are available in most materials and construction lengths. The ball valves are often used in process applications in connection with various media. The advantage of PEKOS ball valves is that they can be built up with different seals that meet requirements for tightness and service life. Seals available are TFM (T) modified Teflon, PEEK, graphite filled or POM.

PEKOS has a comprehensive product range with several variants, such as valves designed with heating jacket, spindle extension and in cryogenic design.

Contact us for more information about these variants.

| Properties |

|

|---|---|

| Technical data |

|

| Technical documentation |

|